32t 36t 39t 43t 47t 54t 59t 64t 72t 77t 80t 90t 100t 120t Polyester Silk Screen Printing Mesh

Basic Info.

| Model NO. | JM-03 |

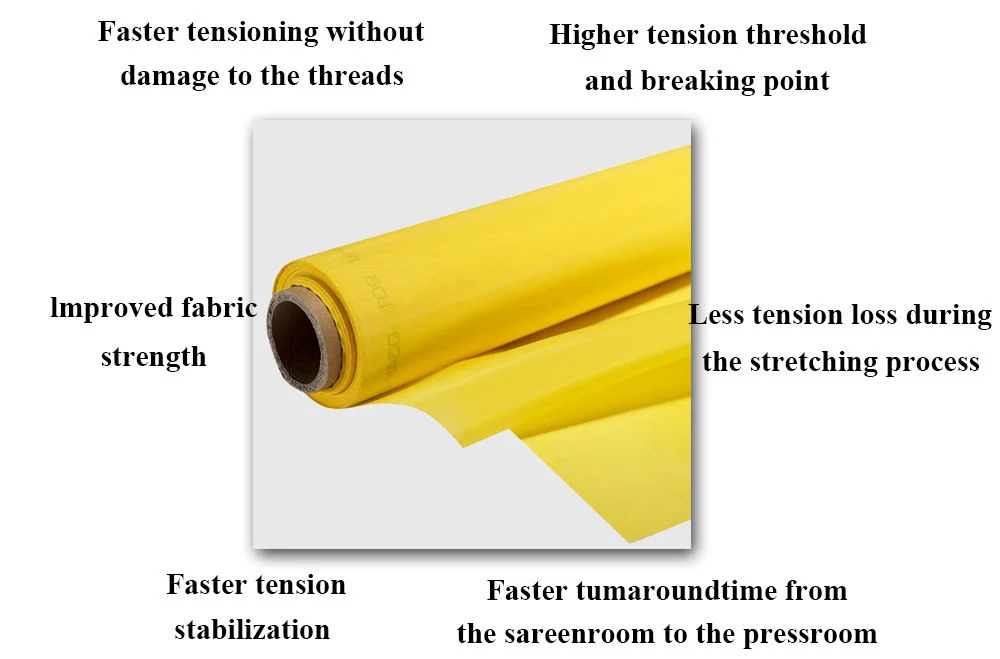

| Feature | High Tension, Low Elongation |

| Roll Width | 157cm, Other Widths Are Available |

| Product Name | Screen Printing Mesh / Polyester Screen Mesh |

| Mesh Count/Inch | 110 Mesh/Inch |

| Mesh Count/Cm | 43t/Cm |

| Transport Package | Standard Export Carton Box |

| Specification | 6t-180t |

| Trademark | JM |

| Origin | China |

| Production Capacity | 2000 Rolls Per Week |

Product Description

Product Description

Screen Printing Mesh is one of best materials for screen printing, drying and filtration in the world.100% monofilament polyester screen printing mesh 43T has high tension and low elongation, with excellent tear resistance and dimensional stability, its mesh count screen are allows for a heavy ink deposit, it's often used for textiles, graphics, PCB, etc printing.

Our Advantages

| Model | JM-03 |

| Material | 100% polyester |

| Woven type | plain woven |

| Mesh count | 30-500 mesh/inch(13 T~165 T ) |

| Wire diameter | 27-200 μm |

| Aperture | 23-680 μm |

| Width | 1.27 m, 1.65 m, 1.83 m, 2.30 m, 3.30 m, 3.60 m, etc |

| Color | white, yellow, etc. |

| Standard length | 50 m/roll |

Choose the Right Mesh Count

60 Mesh - A Course mesh count for use with Glitter Inks. 86/90 Mesh - Recommended for printing opaque white/light colors onto dark fabric to allow maximum opacity. 110 Mesh - Recommended for general textile work, printing light on dark, dark on light. 125/160 Mesh - Recommended for general textile work but with some finer detail/line work. 180/200 Mesh - Textiles; smooth and light fabric, Half-Tone, General. 230/250 Mesh - Textiles; extremely light material, Graphics, General. 305/355 Mesh - Process work

White or Yellow mesh?

White mesh is the more economical of the two, and is primarily seen in lower mesh counts used for less-detailed designs.Higher count mesh is usually dyed yellow because the color yellow acts as a canceling factor for UV light and prevents refraction along the mesh strands when burning your screens. This allows for a more focused and precise exposure, keeping your screens as crisp as possible.